Welcome to the EGGhead Forum - a great place to visit and packed with tips and EGGspert advice! You can also join the conversation and get more information and amazing kamado recipes by following Big Green Egg to Experience our World of Flavor™ at:

Want to see how the EGG is made? Click to Watch

Facebook | Twitter | Instagram | Pinterest | Youtube | Vimeo

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

Restoring Another Offset Smoker and Pork Butts

Comments

-

Agree, this sounds real promising!WeberWho said:Okay, I found it! This sounds promising. At least a place to start.

http://www.bbq-brethren.com/forum/showthread.php?t=111780

And I think you just might break your wife of her love for biscuits. Ha Ha

No, really, great research find on moving the plate around!

I know I owe you a beer for saving me the same headache if this works.

And I was so happy that mine fit so well flush against the firebox side.lol

My cooking chamber is also a little longer at 40”-42”.

Giving the hot air a couple inches to immediately rise might also help draft/pull the whole pit to help even out temps?

added: makes perfect sense that hot air coming out of the fire box would draft better coming into cooker and rising instead of just being slowly diffused at a parallel level with the firebox.Thank you,DarianGalveston Texas -

Round two here we go! The guy from Horizon said 1" gap and the poster in the link above found 2" to work the best. Let's start with 1.5" gap and see where that takes us.

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

There are NO instructions from Horizon on their web site and they show the plate squarely butted up against firebox with ZERO gap. They could be a little more helpful from the start.

http://www.horizonbbqsmokers.com/accessories-1/20-convection-plate

..Thank you,DarianGalveston Texas -

for something different you could do cookie tests as well.Thank you,DarianGalveston Texas

-

.

Might need to build one of these for accurate test results.

OK, I'm getting a little fidgety waiting for results. Sorry.

Thank you,DarianGalveston Texas -

I'm currently moving the convection plate around. I was able to get it down to 25 degrees from front to back. Now I'm at 75 degrees front to back.

I think my fire is too big. I've shut the door and dialed back the vent settings. I'm still getting a blue smoke. So that's promising. That should help. I'm also going to pull out my small log splitter and split these splits down smaller. (Currently the size of a beer can)"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

When you were at 25 degrees apart, what were the 2 temps compared to your main temp gauge?WeberWho said:I'm currently moving the convection plate around. I was able to get it down to 25 degrees from front to back. Now I'm at 75 degrees front to back.

I think my fire is too big. I've shut the door and dialed back the vent settings. I'm still getting a blue smoke. So that's promising. That should help. I'm also going to pull out my small log splitter and split these splits down smaller. (Currently the size of a beer can)Thank you,DarianGalveston Texas -

It seems to be most happy around the 2" mark so far. After making a smaller fire and adjusting the vent settings I decided to move the convection plate back to where I had it yesterday against the firebox and that was a no go. It was a 75 degree difference from end to end.Photo Egg said:

When you were at 25 degrees apart, what were the 2 temps compared to your main temp gauge?WeberWho said:I'm currently moving the convection plate around. I was able to get it down to 25 degrees from front to back. Now I'm at 75 degrees front to back.

I think my fire is too big. I've shut the door and dialed back the vent settings. I'm still getting a blue smoke. So that's promising. That should help. I'm also going to pull out my small log splitter and split these splits down smaller. (Currently the size of a beer can)

So I just switched it back to around the 2"+ mark to see what happens. No biscuits yet. Still trying to find out what makes this thing happy."The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

The bigger the gap the hotter and more even it appears to get from the front to the back but won't stay under 300 degrees. The smaller the gap the more uneven in temperature it becomes from the front to back but closer to the overall temperature I'm looking for.

Lots of guessing and not a whole lot of success.

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

@WeberWho There is a great amount of knowledge to be gained in this thread. However, since we are talking sticks I hope once the challenge is resolved that you pass it on to the other forums you enjoy. Way to keep us all in the loop. I know you will solve this-at least within Q acceptance limits.Louisville; Rolling smoke in the neighbourhood. Life is too short for light/lite beer! Seems I'm livin in a transitional period. CHEETO (aka Agent Orange) makes Nixon look like a saint.

-

Thanks Cap. Unfortunately I don't think this smoker is meant for low and slow cooks. I've been fighting for almost 5 hours now. I've tried big fires, small fires, normal splits, small splits, and have moved this convection plate every possible way. I can't get the temp closest to the firebox to drop below 300 degrees. I now know why my ribs became leather so quickly. I'm just not seeing how I can drop the temp closest to the firebox.

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

You can't give up now.

______________________________________________I love lamp.. -

Turn it into a reverse flow (I know, right when you get it all painted).Weld a floor on it that pipes the firebox effluent to the other side, move the stack, or make it double reverse and leave the stack but split the floor into a path that goes to the stack end, turns around the vents at the firebox end. That might be easier than moving the stack given that stupid door on the firebox. (for grilling, I presume).Or not. Easy for people like me to tell other people what to do.______________________________________________I love lamp..

-

I like the way you think. I have a bigger reverse flow smoker that I'll end up pulling out and using. This one would have been a little more manageable to move around and with smaller cooks. This just might have to become a dedicated grill for high heat cooks. Which isn't all bad as I was concerned that I wouldn't be able to get the temp up past 300 degrees for high heat cooks with the convection plate. Funny how that ended up working out....nolaegghead said:Turn it into a reverse flow (I know, right when you get it all painted).Weld a floor on it that pipes the firebox effluent to the other side, move the stack, or make it double reverse and leave the stack but split the floor into a path that goes to the stack end, turns around the vents at the firebox end. That might be easier than moving the stack given that stupid door on the firebox. (for grilling, I presume).Or not. Easy for people like me to tell other people what to do."The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

If pulling the plate 2” off the box wall balances out your temps the best, but makes your temps run hot, it kinda fits. Letting the air rise from the gap pulls more draft through the smoker, runs hotter. Maybe try choking the stack down by 25% to reduce draft?Thank you,DarianGalveston Texas

-

I'm with @Photo Egg. Different animal here but I leave the firebox vents wide open and do throttle the exhaust. That definitely creates noticeable temperature drops. Also I will throttle the grease drain on the bottom of the rig, another trick that works as both combine to redirect the fire gasses out the downwind side of the firebox.

No skilled pit master here but just a few things I have come across in the years of reading and messing about with sticks. FWIW-

You will get this!Louisville; Rolling smoke in the neighbourhood. Life is too short for light/lite beer! Seems I'm livin in a transitional period. CHEETO (aka Agent Orange) makes Nixon look like a saint. -

I tried playing around with the exhaust earlier but It was also with the bigger size splits. I'll give it a try here.

I also just cut my splits in half to see if my split splits are still too much."The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

I just went to check on my smaller split splits and I'm over 300 degrees with the two inch gap. This smoker just doesn't make any sense...."The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

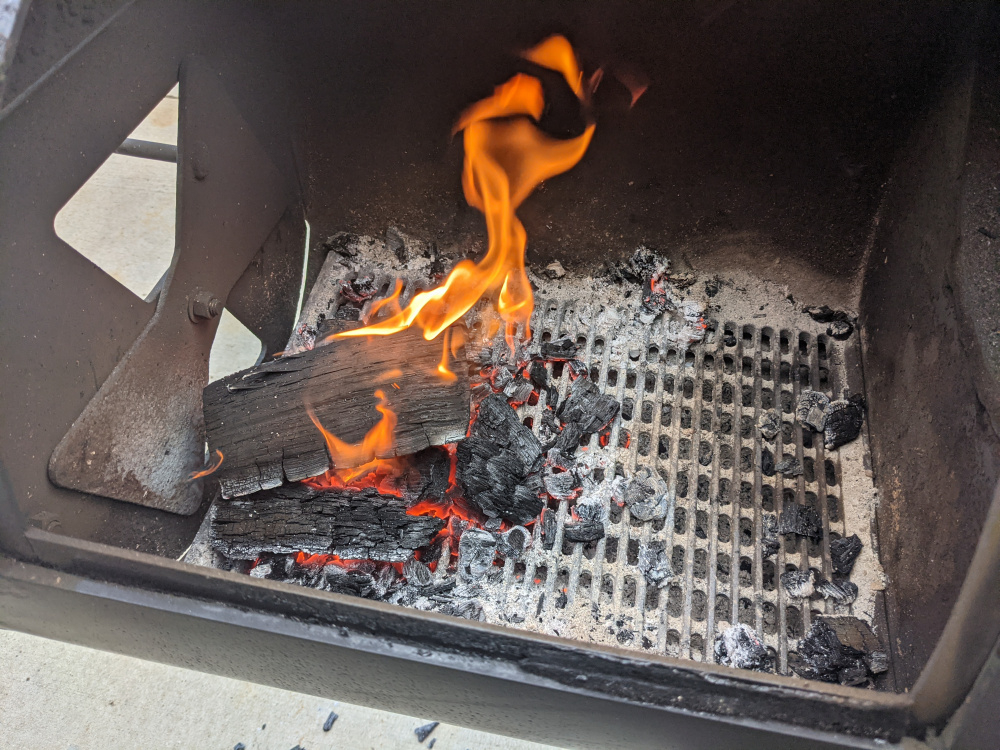

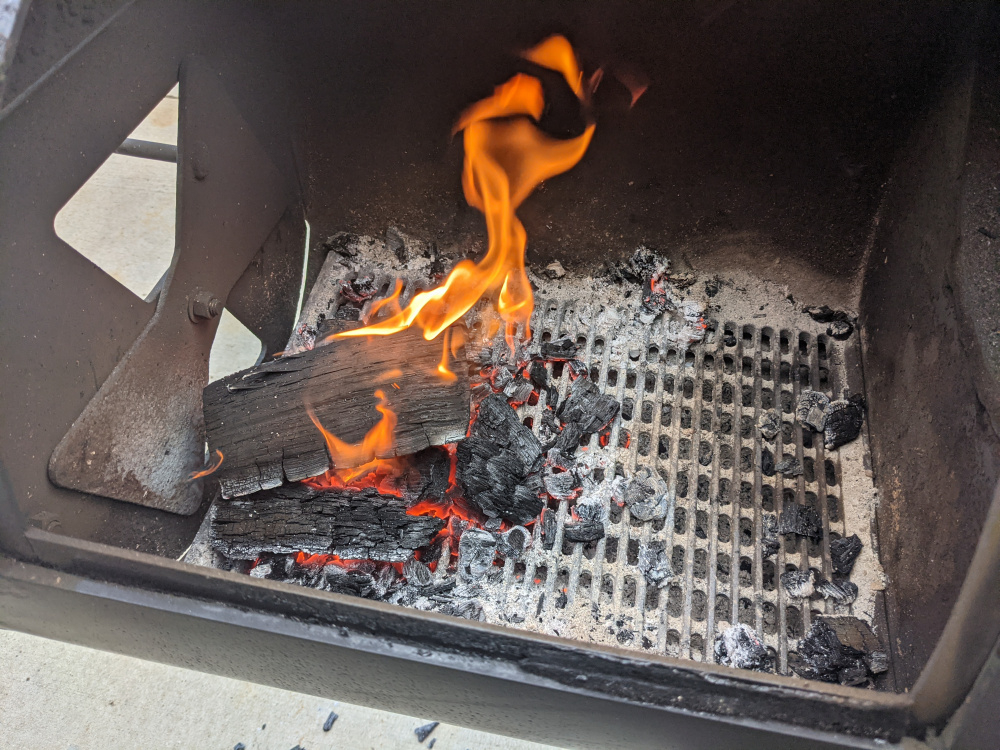

I don't think I can get much smaller for a fire. I'm still pulling 310 near the firebox. I opened up the firebox vent and partially closed the exhaust.

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

Sure seems like you should be able run at 250ish with much more of a coal bed than you have there. Maybe go hard by shutting down your stack by 75% and see what happens. You have tried everything thing else I can think of.WeberWho said:I don't think I can get much smaller for a fire. I'm still pulling 310 near the firebox. I opened up the firebox vent and partially closed the exhaust. Thank you,DarianGalveston Texas

Thank you,DarianGalveston Texas -

I would go with the fire box vents wide open and then work back from there. But I have to say that the small size of that fire and your temperature issues are definitely outliers to me. At some point this has to all come together-easy for me to say.Louisville; Rolling smoke in the neighbourhood. Life is too short for light/lite beer! Seems I'm livin in a transitional period. CHEETO (aka Agent Orange) makes Nixon look like a saint.

-

She didn't like the exhaust being messed with.

I opened up the exhaust and have the firebox vent fully open. She's currently within 10 degrees from front to back according to the thermometers for the last 5 minutes. It doesn't like anything but a small fire. Probably a fluke but I'll take anything at this point!"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

No way that's right for the fire but sure is nice to see 250 even if the fire is completely wrong.

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

The only major difference I can see is fire position. I got better results keeping my fire in the back of the box next to chamber wall. As I added more wood to the front as needed. This kept the new wood smoke going through the heat and flames of the stable fire. This helped keep my smoke cleaner. I would then push the coals back as needed and add more wood.

When you say it does’t like you to shut down the top vent, what happens?Thank you,DarianGalveston Texas -

@WeberWho - scrolling back thru your pics your fire box vent arrangement is totally different than what I work with. I have two good sized vents on each side of the box thus a good flow-thru air flow. I'm sure your setup would lead to much different responses from throttling the exhaust. FWIW-Louisville; Rolling smoke in the neighbourhood. Life is too short for light/lite beer! Seems I'm livin in a transitional period. CHEETO (aka Agent Orange) makes Nixon look like a saint.

-

Sorry, I meant the exhaust.Photo Egg said:The only major difference I can see is fire position. I got better results keeping my fire in the back of the box next to chamber wall. As I added more wood to the front as needed. This kept the new wood smoke going through the heat and flames of the stable fire. This helped keep my smoke cleaner. I would then push the coals back as needed and add more wood.

When you say it does’t like you to shut down the top vent, what happens?

I added a bigger split because that little fire isn't going to cut it. The front thermometer is up and past 300 degrees. I might have to cut them up into chunks to see if that helps at all. Small splits appear to be way too hot for this smoker and a little baby fire isn't going to work.

I'm done for the night and running out of options. I just don't get it....."The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

Agree, very frustrating. I knew what you were talking about. But what bad happens when exhaust is slowly closed down after you have established fire?WeberWho said:

Sorry, I meant the exhaust.Photo Egg said:The only major difference I can see is fire position. I got better results keeping my fire in the back of the box next to chamber wall. As I added more wood to the front as needed. This kept the new wood smoke going through the heat and flames of the stable fire. This helped keep my smoke cleaner. I would then push the coals back as needed and add more wood.

When you say it does’t like you to shut down the top vent, what happens?

I added a bigger split because that little fire isn't going to cut it. The front thermometer is up and past 300 degrees. I might have to cut them up into chunks to see if that helps at all. Small splits appear to be way too hot for this smoker and a little baby fire isn't going to work.

I'm done for the night and running out of options. I just don't get it.....Thank you,DarianGalveston Texas -

Small fire, vents wide open, and try cracking the grill lid on the firebox to divert a little effluent from the smoke chamber. If that works maybe weld in a 1.25-2" npt nipple and put a ball valve on it. A bypass system. Also useful for cold smoking______________________________________________I love lamp..

-

Im in this camp, wide open and control by the source ...i still think I would increase the draw on this( stack height )..the other issue is sometimes these smaller fire boxes are better suited to lump//coal with splits for flavorlousubcap said:I would go with the fire box vents wide open and then work back from there. But I have to say that the small size of that fire and your temperature issues are definitely outliers to me. At some point this has to all come together-easy for me to say.

Excellent project and threadVisalia, Ca @lkapigian -

If you’re getting clean smoke and pit temps are actually higher than needed, why would you increase the draw to stoke the fire more and burn more fuel?lkapigian said:

Im in this camp, wide open and control by the source ...i still think I would increase the draw on this( stack height )..the other issue is sometimes these smaller fire boxes are better suited to lump//coal with splits for flavorlousubcap said:I would go with the fire box vents wide open and then work back from there. But I have to say that the small size of that fire and your temperature issues are definitely outliers to me. At some point this has to all come together-easy for me to say.

Excellent project and threadNot saying it’s the wrong move, just trying to understand.Thank you,DarianGalveston Texas

Categories

- All Categories

- 184.1K EggHead Forum

- 16.1K Forum List

- 461 EGGtoberfest

- 1.9K Forum Feedback

- 10.5K Off Topic

- 2.4K EGG Table Forum

- 1 Rules & Disclaimer

- 9.2K Cookbook

- 16 Valentines Day

- 118 Holiday Recipes

- 348 Appetizers

- 521 Baking

- 2.5K Beef

- 90 Desserts

- 167 Lamb

- 2.4K Pork

- 1.5K Poultry

- 33 Salads and Dressings

- 322 Sauces, Rubs, Marinades

- 548 Seafood

- 175 Sides

- 122 Soups, Stews, Chilis

- 44 Vegetarian

- 103 Vegetables

- 315 Health

- 293 Weight Loss Forum