Welcome to the EGGhead Forum - a great place to visit and packed with tips and EGGspert advice! You can also join the conversation and get more information and amazing kamado recipes by following Big Green Egg to Experience our World of Flavor™ at:

Want to see how the EGG is made? Click to Watch

Facebook | Twitter | Instagram | Pinterest | Youtube | Vimeo

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

Outdoor table build progress

Comments

-

Thanks. I flooded the area with a hose and it drains. The slab is pitched in the right direction. The L shape is not a 90 but about 130 so it doesn't trap water.XL BGE and Kamado Joe Jr.

-

Installed the slabs. Now trying to figure out what size circles to cut in the cement board. I need a cloth tape measure.

XL BGE and Kamado Joe Jr. -

-

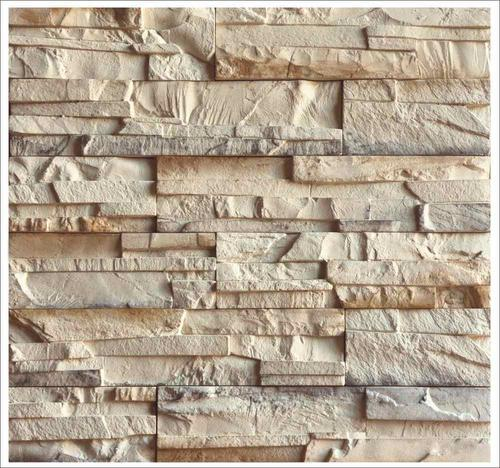

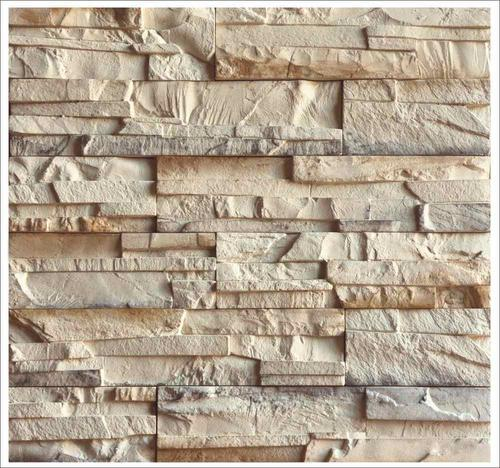

I keep changing my mind on what kind of veneer to use. Right now I am leaning towards cultured ledger stone, thinking slate might delaminate from constant freeze/thawing (see below for the cultured stone I am thinking of using). I have seen it on slate pavers. Not so much on outdoor siding, but that stuff is usually 1-1.5in thick. I can only fit a max of .75. Most of that stuff says indoor/outdoor but you only really see it indoors. Other natural stones (not slates) are crazy expensive for this project (15 to 25 bucks sq ft).

XL BGE and Kamado Joe Jr.

XL BGE and Kamado Joe Jr. -

-

That's a lot of blood, sweat and tears you've put in this project to turn around slap some fake stone veneer on. I'd rather just do stucco. How much is flagstone in your area? That would make a good durable natural veneer and isn't overly thick.South of Nashville - BGE XL - Alfresco 42" ALXE - Alfresco Versa Burner - Sunbeam Microwave

-

You might give some thought to coating the Durock with RedGard prior to veneer. It will make the board waterproof, can usually get it at Home Depot.MMBGE / Large BGE / XL BGE (Craigslist Find) / SF30x80 cabinet trailer - "Ol' Mortimer" / Outdoor kitchen in progress.

RECOVERING BUBBLEHEAD

Southeastern CT. -

@speed51133 thanks for posting. Beautiful project.

Where did you source those fascinating round metal flanges?

I don’t recall seeing those on other table builds. -

I can relate. Pictured is black natural ledger stone. Mine is just on top and accent and its ridiculously high priced as well as fragile when cutting. Its chips so easily. Im excited about your build. Also love the egg circle rings. Great idea. Wish i would of thought of it. I put a drawer under my egg. The drawer width screwed me from enclosing the egg like you did. Love that look.speed51133 said:I keep changing my mind on what kind of veneer to use. Right now I am leaning towards cultured ledger stone, thinking slate might delaminate from constant freeze/thawing (see below for the cultured stone I am thinking of using). I have seen it on slate pavers. Not so much on outdoor siding, but that stuff is usually 1-1.5in thick. I can only fit a max of .75. Most of that stuff says indoor/outdoor but you only really see it indoors. Other natural stones (not slates) are crazy expensive for this project (15 to 25 bucks sq ft).

Columbus, Ohio -

Thanks for the comments. The ring is plastic. It is just a form for the concrete. It breaks off after the concrete is cured.

https://www.concretecountertopsolutions.com/product/bendable-square-form

I have matching forms to install around the island I have yet to install. It's 27 degrees right now, might not do it today.XL BGE and Kamado Joe Jr. -

-

Coming along great. You have inspired me. I've been looking at that concrete counter website you posted. Don't forget to vibrate and vibrate again. Have fun Saturday!XL BGE

Malden, MA -

Im excited for you. Weather permitting i will have my countertop tomarrow...Columbus, Ohio

-

Fahkin' bada$$

=======================================

XL 6/06, Mini 6/12, L 10/12, Mini #2 12/14 MiniMax 3/16 Large #2 11/20 Legacy from my FIL - RIP PitBoss Navigator 850G 11/25

Tampa Bay, FL

EIB 6 Oct 95 -

I just started making plans for a new table to house a large and a MiniMax. And based on the bananas-level construction of this monster, I will not be showing you my table.

It reminds me of the old Johnny Carson show where Bob Hope, Dean Martin were on the panel, and George Gobel came out third. He said "You ever get the feeling that the world was a tuxedo, and you were a pair of brown shoes?"

Seriously, nice work. You guys have crazy talent. Looking forward to seeing the finished product.LBGE since June 2012

Omaha, NE

-

Really nice.

-

-

-

Looks good, those guys are not afraid of making a mess!

South of Columbus, Ohio. -

-

-

Sorry I didn’t recognize you without your earringSouth of Columbus, Ohio.

-

Really fantastic project- you are going to love that setup and will appreciate it even more with all of your sweat equity.Greensboro, NC

-

-

I didn't get the joke. Sorry 🤨alaskanassasin said:Sorry I didn’t recognize you without your earringXL BGE and Kamado Joe Jr. -

I didn’t realize that was you working the concrete top, don’t know what you look like, didn’t get a card last Christmas. Keep up the good work buddySouth of Columbus, Ohio.

-

Oh, I just assumed everyone looks at the closeup of my profile pic. I'd gladly include you in the Christmas card list. Please provide address.XL BGE and Kamado Joe Jr.

-

-

This thread slowed down. Any updates?

LBGE since June 2012

Omaha, NE

-

Haha. It did indeed. That is mostly because of setback that was really disappointing. I mixed the concrete with a retarder to give me more time to work the mix. Unfortunately the retarded reacted poorly with the mix. The concrete manufacturing company was very helpful but ultimately stated they do not test it for all conditions. Note, adding retarders is a very normal thing in the concrete world.

The overall effect was the surface never really cured after 4 days. It was like clay. I took out the diamond grinder and grind it all down until it was solid. Here is the worst part the rest was about 1/8 to .25in.

The part I dug out in the picture was like oatmeal after 4 days. It actually cured solid in the door pit after a few more days. Who knows if it works have been ok.

I repoured the dug out area and used a bonding adhesive for the cold joint. I then roughened out the new pour. All the top corner edges of the slab were really soft. So I chiseled them all if and used a special mix to fix them and ground it back to a sharp edge.

Now I will be adding a topical overlay skim coating to make it all even and smooth. I'll be doing that today.

This was very frustrating and disappointing but I was able to salvage it. In retrospect I should have had 4 people helping and no retarder. I used a drum mixer and the concrete manufacturer said I should have used a paddle and 5 gal bucket to really agitate the polymers in each bag of the mix. I used the drum to speed it up. The mix sets so fast. By the time you are in the second bucket the first is already not flowing. I used a total of 15 bags. So 3 guys mixing with buckets and one pouring and screedning. Not really practical when a diy protect. A different mix would have helped but this was all I can get locally. Online orders had about 150$ in freight.

I'll update Monday.

XL BGE and Kamado Joe Jr.

Categories

- All Categories

- 184.1K EggHead Forum

- 16.1K Forum List

- 461 EGGtoberfest

- 1.9K Forum Feedback

- 10.5K Off Topic

- 2.4K EGG Table Forum

- 1 Rules & Disclaimer

- 9.2K Cookbook

- 16 Valentines Day

- 118 Holiday Recipes

- 348 Appetizers

- 521 Baking

- 2.5K Beef

- 90 Desserts

- 167 Lamb

- 2.4K Pork

- 1.5K Poultry

- 33 Salads and Dressings

- 322 Sauces, Rubs, Marinades

- 548 Seafood

- 175 Sides

- 122 Soups, Stews, Chilis

- 44 Vegetarian

- 103 Vegetables

- 315 Health

- 293 Weight Loss Forum