Welcome to the EGGhead Forum - a great place to visit and packed with tips and EGGspert advice! You can also join the conversation and get more information and amazing kamado recipes by following Big Green Egg to Experience our World of Flavor™ at:

Want to see how the EGG is made? Click to Watch

Facebook | Twitter | Instagram | Pinterest | Youtube | Vimeo

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

OT: saw question :OT

ryantt

Posts: 2,559

I’ve decided I’d like to start playing with wood...I would like to purchase a few basic shops tools. A compound miter saw, table saw, and so on. As a person just getting started, can you make a some recommendation... @nolaegghead @bubbajack or others.

Thanks in advance

XL BGE, KJ classic, Joe Jr, UDS x2

Comments

-

Buy once cry once. Especially when it comes to a miter and tablesaw. Get something quality the first time around. Even if it's not your thing you'll be able to get most of your money back selling it if it's a quality tool.

It will also depend on what kind of room you have available for tools. A smaller portable tablesaw and a commercial tablesaw are two different animals. One saw can be tucked away and stored within reason and others will take up real estate. Do you have a permanent place or is it something you want to move around from one place to another when in use?"The pig is an amazing animal. You feed a pig an apple and it makes bacon. Let's see Michael Phelps do that" - Jim Gaffigan

Minnesota -

I got into woodworking a bit back, I’ll say at the time I was broke and I still have the mostly the same tools. Cheapest delta direct drive 10” table saw, craftsman electric drill (not battery), and a ton of hand tools. Later added on a drill press, miter saw, band saw and I jumped the shark with a planer that has barely been used. I don’t do fine crafted furniture, but I’ve done good basic beds, coffee tables, end tables, a pergola, shed, etc. you can get 98% there with basic tools and know how. The good tools make life (much) simpler. Also - highly recommend second hand tools. I got my 19” delta band saw for under $100. It’s a piece of crud, but it’s cheap and does its job.On this specific forum, I thought there would be more shopsmith folks. It’s the egg of power tools. 😁+++++++++++++++++++++++++++Austin, Texas. I'm the guy holding a beer.

-

How much do you want to spend? $, $$, $$$, $$$$ ?

“Reality is that which, when you stop believing in it, doesn't go away.” ― Philip K. Diçk -

@WeberWho I have a 3rd car garage spot that I can use. This space is also extended so I have a 14x30 area that I can use. I am ok with buying once and crying once, just do not know what to buy.

XL BGE, KJ classic, Joe Jr, UDS x2 -

@HeavyG I haven't set a budget yet, and figure I will add as I go...Let say 3k to start buying tools.

@sumoconnell I really just want to build things for around the house. I love the idea of being able to make a nice farm style table or hall tree for the entry way. I would also like to be able to just play and figure out what I likeXL BGE, KJ classic, Joe Jr, UDS x2 -

What @WeberWho just said about buy once cry once...BUT I really do have to add some other thoughts. 1) is this possibly a passing whim much like other ideas? No offense meant, but getting into having a good woodworking shop is not inexpensive and trust me will lead you down more expensive "dark alleys" than you know! 2) have you really done much woodworking before? Buzzing some boards for a small outdoor project where sloppy corners are ok - is nothing like getting into what I call "woodworking for a satisfying hobby".Re-gasketing the USA one yard at a time

-

@RRP I grew up working with my uncles who own a cabinet shop/ construction company. As a young person I enjoyed making things with them...outside of that I've only done small projects around the house. I've always just driven to the shop when I wanted to play...these days, I would like to be able to walk out to the garage and "play". I think that this would be a good stress reliever and way of decompressing from the work day.

So to answer the question, not much experience, but enough to know that what I've done I've enjoyed. I think starting off small with basic tools would be a good way to gage if it will stick. Ive asked my uncles but all they say is just go to the shop...XL BGE, KJ classic, Joe Jr, UDS x2 -

No offense, but a 3rd car garage may be fine for some parts of the country, but in OH means the other 2 parts of the garage will probably mean parking wet cars...right? GOOD stationary tools normally have cast iron tables, much less hidden iron parts. Rust is a continuous problem and don't think for a minute that it won't be! And fighting that rust is a b*tch! Are you sure you don't just want to take up golf and give your uncles a case of beer to use their workshop or to build what you want?ryantt said:@WeberWho I have a 3rd car garage spot that I can use. This space is also extended so I have a 14x30 area that I can use. I am ok with buying once and crying once, just do not know what to buy.Re-gasketing the USA one yard at a time -

@RRP played golf most of my life, it is no longer in the cards...i can no longer turn like I use to. Do you think it would be better to build out a shop area in the basement? It is unfinished and I could dedicate half or so to the hobby

(lets say 1500 sq feet for me). I am wanting to start basic and move forward if i truly enjoy it.XL BGE, KJ classic, Joe Jr, UDS x2 -

Woodworking can be simple in a way or very complicated. Simple is better.

I drink cheap beer so I can afford good bourbon.

Salisbury, NC...... XL,Lx3,Mx2,S, MM, Mini BGE, FireDisc x2. Blackstone 22", Offset smoker, weber kettle 22" -

First designing and then building a separate workshop complete with all planned out lighting, all electrical service, all buried dust collection tubes etc etc is any serious wood worker's DREAM!ryantt said:@RRP played golf most of my life, it is no longer in the cards...i can no longer turn like I use to. Do you think it would be better to build out a shop area in the basement? It is unfinished and I could dedicate half or so to the hobby

(lets say 1500 sq feet for me). I am wanting to start basic and move forward if i truly enjoy it.Re-gasketing the USA one yard at a time -

Ryan, I've used the same basic setup for about 30 years now, and I'm restricted by space. My thoughts, but your situation may be different.

Get a good tablesaw. Mine's a Delta, just a contractor-level, but as @WeberWho said, it depends on your space; I can't cut an 8' sheet of plywood lengthwise, without stopping the saw and sliding it towards me to complete the cut. Not ideal, but it's what I have. I don't have a compound miter saw, nor do I want one. I've built a sliding table sled that fits on my tablesaw, giving me perfect 90- and 45-degree crosscuts; anything more than that (picture frames and la-dee-da boxes) I have a precision miter box (manual) that gets me by for those things.

When I left Air Force Active Duty, I got a chunk of change to pay off the 20% down-payment on my house here, plus a Delta bandsaw and a $3,000 Jointer/Planer (unlike @sumoconnell I attended dozens of farm sales, in ND, for three years in the freezing rain or blizzards, only to watch other desperate folk bid up to -$10 (I'm not kidding) of the price of a brand-new Delta. I bought my (new) one here in utard). A bandsaw is a joy, and some will insist that, if you only have one power tool, it should be a bandsaw (I still vote for a tablesaw, but it depends on what you want to build).

My jointer/planer. It was a swedish "Inca", allowed me to build precision casework from felled trees, I loved it, but once its rubber belts aged and its nylon gears stripped (and they went bankrupt), I had a $3,000 paperweight. I'm still sick about this. Find a lumber dealer who will roughly plane your stock, and then learn to use a hand smoothing plane; I wish I'd done that.

Finally, a sturdy workbench is actually one of the best things you can invest in. I'd suggest watching for used ones. Mine is half-self-built and half commercial (the top, and its now warped). Mine is also as heavy as I am (well, 20 years ago). It makes a difference, especially if you rely on hand tools a lot, like I do:

"Dumplings are just noodles that have already eaten" - Jon Kung

Ogden, UT, USA

-

Envious of your 3rd garage spot and unfinished basement. But more envious of having access to uncles and a professional wood shop. I would come up with a few projects to complete at their place first and see where that takes you.

-

Love your advice and your tool cabinet...plus I see some early Bridge City tools Which I also have plus some more. I received an unexpected bonus check of $1,500 way back in 1984 and spent it all on a 10" Delta UniSaw and have never regretted it! Too bad about your $3k paperweight. I've stuck to Delta for most of my stationery tools, except for some Ryobi products and even Sears back when they still were healthy and PROUD!Botch said:Ryan, I've used the same basic setup for about 30 years now, and I'm restricted by space. My thoughts, but your situation may be different.

Get a good tablesaw. Mine's a Delta, just a contractor-level, but as @WeberWho said, it depends on your space; I can't cut an 8' sheet of plywood lengthwise, without stopping the saw and sliding it towards me to complete the cut. Not ideal, but it's what I have. I don't have a compound miter saw, nor do I want one. I've built a sliding table sled that fits on my tablesaw, giving me perfect 90- and 45-degree crosscuts; anything more than that (picture frames and la-dee-da boxes) I have a precision miter box (manual) that gets me by for those things.

When I left Air Force Active Duty, I got a chunk of change to pay off the 20% down-payment on my house here, plus a Delta bandsaw and a $3,000 Jointer/Planer (unlike @sumoconnell I attended dozens of farm sales, in ND, for three years in the freezing rain or blizzards, only to watch other desperate folk bid up to -$10 (I'm not kidding) of the price of a brand-new Delta. I bought my (new) one here in utard). A bandsaw is a joy, and some will insist that, if you only have one power tool, it should be a bandsaw (I still vote for a tablesaw, but it depends on what you want to build).

My jointer/planer. It was a swedish "Inca", allowed me to build precision casework from felled trees, I loved it, but once its rubber belts aged and its nylon gears stripped (and they went bankrupt), I had a $3,000 paperweight. I'm still sick about this. Find a lumber dealer who will roughly plane your stock, and then learn to use a hand smoothing plane; I wish I'd done that.

Finally, a sturdy workbench is actually one of the best things you can invest in. I'd suggest watching for used ones. Mine is half-self-built and half commercial (the top, and its now warped). Mine is also as heavy as I am (well, 20 years ago). It makes a difference, especially if you rely on hand tools a lot, like I do:

Re-gasketing the USA one yard at a time -

Was kind of hoping this would be about the movie.@PeteSliver, RIP

-

-

Location- Just "this side" of Biloxi, Ms.

Status- Standing by.

The greatest barrier against all wisdom, the stronghold against knowledge itself, is the single thought, in ones mind, that they already have it all figured out. -

Over the course of the last 10-12 years, I've slowly built my arsenal of tools to support a hobby. I am FAR from a decent woodworker, but it's nice to be able to fabricate something from nothing. Shelving, workbenches, a farmhouse desk, a couple Egg tables. Nothing I've made would be considered fine craftsmanship, but it's all usable, and is cheaper than store bought. Most importantly, it scratches an itch to be creative, especially when it's cold outside and I can't golf or fish.

I'll echo the recommendations to invest in a good workbench. I built a 4x8' rolling workbench at the exact same height as my table saw. Theoretically I can use it as an outfield table. Realistically, it's a huge flat area in the garage that most often collects crap I'm too lazy to put away, but when I need it it's pretty awesome.

Beyond that, the tools I use most include:

Dewalt jigsaw

Kobalt portable table saw

18V Lithium Ion drill/impact driver combo

Dewalt orbital sander

Ryobi compound miter saw

Ridgid shop vac

and, not a tool, but super important: respirator mask. Don't breath in sawdust!

Tools I love but don't use often:

- Masterforce Track Saw (w/8 foot track)

- Masterforce Drill Press (used once, but perfectly vertical holes were money

- Ryobi multi-tool

But perhaps the most important tool/gadget in my shop is the Kreg pocket hole jig system. Spring for the K4 master system. It's about $140, but it is so helpful. Not everything I make is beautiful, but anything I make with pocket holes is bombproof.

I also have quite a bit of crap from Harbor Freight. I have an HVLP paint gun, a reciprocating saw, heat gun, electric planer, clamps (you can never have enough), etc etc. Plus, before COVID, that was the place to get boxes of nitrile gloves on the cheap. I read reviews before I buy anything there. They sell a lot of stuff that's absolute trash, but there are some hidden gems, especially if you don't plan on using them often.

LBGE since June 2012

Omaha, NE

-

You mentioned building a farmhouse table. This was done primarily with a miter saw and a Kreg Jig. Relatively easy, but functional and fun.

LBGE since June 2012

Omaha, NE

-

Woodworking is an ancient skill predating spoken language and traceable back to early hominids, where ant-fishing sticks were fashioned and spears constructed to settle early internet arguments with prejudice.I've gone through several generations of tools as I couldn't afford decent ones when I was younger. Before that, I "borrowed" my dad's tools (he didn't have decent ones either).Anyway, my current choices are, I believe, practical with a moderate budget.Obviously there are many different types of projects and depending on what you're doing, different tools will be more important. My selection is geared towards general fine woodworking, although I have tools for wood construction and miniature wood projects.(this is all subject to disagreement, depending on who you are...)I like precise tools where I can dial in a measurement and there's not much room for interpretation on what will be cut.The table saw is my most used tool. If you are working with large dimension lumber, you may need a band-saw for re-sawing lumber to your rough dimensions. Depends on what you're doing. I have both. My band saw will also cut curves, but I don't use it very often for that.If you have the space, get a full-sized table saw. If you have the money, get a cabinet saw (motor is in a cabinet rather than hanging off the back). Having an outfeed table makes sawing large lumber easy. I have a roller outfeed table that folds out of the way when I don't need it. A workbench will work fine. Some people build a workbench around their table, but you need lots of space.Maybe equally used is a miter saw. Compound miter gives you two axes of adjustable angle. Botch's hand-saw miter box is admirable, but IMO a powered miter saw is essential.If you are dealing with imperfect lumber, which is almost all lumber, you probably want a joiner, which makes one side of the wood a single plane (also relative to another). If you have two sides of a board square, you can make all of them square, and anything you cut off of them square. (90 deg angles). A table saw or band saw will also work so you don't need this. If you want to make end-grain cutting boards, it's mandatory.Planer - great if you're dealing with rough cut wood or can't get the exact thickness you want. Try to avoid using a planer when possible. It's a crutch for some people.Router - essential. You probably also want a router table.Drill press - essential depending on what you're doing. You can get a guide for a hand drill if you just want square holes.Mortising machine - very useful if you want mortise and tenon joints - you can get a drill press attachment that does the same thing, and you can use a regular drill and chisels to do it old-school.Powered hand tools - time savers. You probably have this stuff already.Joinery - If you want to build something that lasts, you don't use fasteners, you use wood and sometimes glue. Pocket joints are fast and convenient, but they don't hold up for the most part if you're making heritage furniture that lasts for generations. Wood screws have their place. Pin, brad and finishing nails are fine (to hold while glue sets) if you're in a hurry. Screws replace "proper" joinery like tongue and groove, rabbits, dovetails/finger joints, mortise and tenon, etc. Nothing wrong with metal fasteners other than durability concerns.You can never have enough clamps.I could write a book on this, I'm just scratching the surface.If you want some concrete options:Cabinet table saw with biesemeyer fence. Grizzly, Delta, Powermatic, etc.Miter saw - I have a $600+ Milwaulkee and a $370 HF. I prefer the HF Hercules. I have had lots of others. A compound sliding is nice to have. A saw stand or custom made rig for it is a must-have. You can go crazy here and get a Festool Kapex, but your project won't be better.More to follow.______________________________________________I love lamp..

-

I PM'd you my number. I'll go into more detail on the phone.I probably have $10K in Festool stuff. To me it's worth every penny. I highly recommend the Domino system and the Rotex 150 sander. I use those tools the most. The rail saw is nice but the table saw will do most everything it will. The dust extractor is ridiculously expensive for a vacuum, but if you use it with the tools, you'll understand why.I have a lot of good measuring tools.Getting your saws aligned is mandatory. It's a PITA, but once done, you will trust them.Learning how wood expands/warps/twists will make everything much smoother in the construction phase. If you don't, you can spend hours building something that ends up self-destructing with a humidity change (if your AC fails or you put it outside).My next big purchase will be a portable mill. (and another dust extractor) Probably will get a Wood-mizer.Get at least a couple metric measuring devices. Makes the math easy when you're trying to divide or find centers. I use both the English and metric system regularly depending on what I'm doing.______________________________________________I love lamp..

-

Ryan,

I will hop onto what @nolaegghead said above. For hand tools you can’t beat Festool. They are expensive, very well made, dust collection is an integral part of the design, and they have great repeatability and precision (important for making multiple parts). Unlike Nola I use my Festool track saw quite a bit for breaking down sheet goods. Much easier for a single person to do that as opposed to trying to man-handle a full sheet on a table saw.

Don’t skimp on dust collection. Wood dust has long been known to be a serious health hazard (https://www.osha.gov/SLTC/etools/sawmills/dust.html). Wear at least a dust mask, even with a good DC system.

For your table saw, I highly recommend SawStop. They aren’t cheap, and some people call them a gimmick, but when you can put your finger into a running blade and come away with just a scrape, I’m a believer. https://youtu.be/CX9nGSpoi8E. They are also built really well. Did I mention table saws are the most frequent cause of wood shop injuries? https://www.canadianwoodworking.com/top-ten/top-10-most-dangerous-woodworking-machines-and-toolsI have two miter saws - the cheap DeWalt on the left has a 40T blade and is used for rough cuts. The sliding Metabo on the right has an 80T blade and is used where finer cuts are required.I am just getting around to setting up my shop in my 3-car garage (36’ x 26’) and am running out of room. It can be done in a smaller space with good planning and mobile tools bases.

I still need to add a bandsaw and a drum sander but I’m getting there.

Oh, head over to www.sawmillcreek.org and do some reading, you will get tons of solid advice from pros and hobbyists. Keep checking Craigslist for good used tools, you can score some amazing bargains.

MMBGE / Large BGE / XL BGE (Craigslist Find) / SF30x80 cabinet trailer - "Ol' Mortimer" / Outdoor kitchen in progress.

MMBGE / Large BGE / XL BGE (Craigslist Find) / SF30x80 cabinet trailer - "Ol' Mortimer" / Outdoor kitchen in progress.

RECOVERING BUBBLEHEAD

Southeastern CT. -

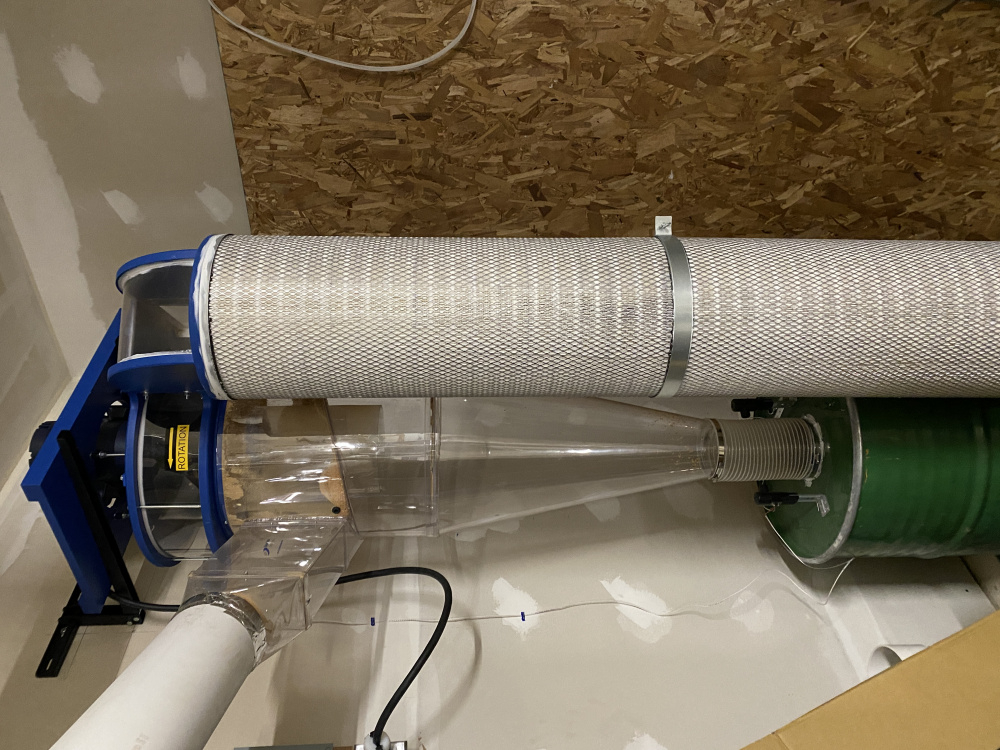

Nola, check out ClearVue for your next DC. It works great, has crazy suction (I upgraded to the 16” impeller). If you look close at the lid of the 55 gal drum, I have a couple of garage door sensors. When the sawdust breaks the beam due to being full, it stops the DC, and sets off a strobe light and horn for visual and audible warning (great when the jointer or planer is running).nolaegghead said:My next big purchase will be a portable mill. (and another dust extractor) Probably will get a Wood-mizer.Are you going to build a solar kiln to go with that Wood-Mizer?MMBGE / Large BGE / XL BGE (Craigslist Find) / SF30x80 cabinet trailer - "Ol' Mortimer" / Outdoor kitchen in progress.

RECOVERING BUBBLEHEAD

Southeastern CT. -

Not to take too divergent a turn, but the best money I ever spent was on my brain. Look at any local junior college, or community college, and see if they have any programs in Cabinetmaking. I took a two year certificate program at the local CC, and it was only two nights a week and well worth it. After that you will be much better informed to start out appropriately. You can do 95% of what you need with hand tools, and get the rest done for you by others. You'll have a much more pleasant time in the shop, and not worry about dust or space. Start with a solid bench and a few quality hand tools. There are many references out there on what to get. Eventually you can add a few key power tools, like a table saw or a band saw. If it takes off, add more as necessary.

Bob

New Cumberland, PA

XL with the usual accessories -

dont forget the hand saws

fukahwee maineyou can lead a fish to water but you can not make him drink it -

Love your shop setup, @CTMike!

"Dumplings are just noodles that have already eaten" - Jon Kung

Ogden, UT, USA

-

-

@CTMike Nice shop! I'm jelly of your Powermatics.I actually ordered a 2nd dust extractor last night. The Festool CT15 has been out of stock everywhere so I ordered the smaller Fein with a 5.9G tank. I need it for my Gretna shop where I keep all my wood - I try to rough cut it there and then bring to my house shop where I have the beast Festool CT26.I have a couple big shop dust collectors....one is the Grizzly and the other a cheaper HFNeed to plumb those up to the big tools.Metal working stuff is another rabbit hole. I have to admit that I'm pretty diversified on shop equipment.I'm trying to get a Grizzly drum sander re-furbed that I bought on CL. That will be a nice addition.______________________________________________I love lamp..

-

Nice. The first Festool pieces that I bought were the Domino 700XL, the Rotex 125 (wish I went with the 150), and the CT36. The Festool vacuums are an amazing piece of kit and well worth the price.nolaegghead said:@CTMike Nice shop! I'm jelly of your Powermatics.I actually ordered a 2nd dust extractor last night. The Festool CT15 has been out of stock everywhere so I ordered the smaller Fein with a 5.9G tank. I need it for my Gretna shop where I keep all my wood - I try to rough cut it there and then bring to my house shop where I have the beast Festool CT26.I have a couple big shop dust collectors....one is the Grizzly and the other a cheaper HFNeed to plumb those up to the big tools.Metal working stuff is another rabbit hole. I have to admit that I'm pretty diversified on shop equipment.I'm trying to get a Grizzly drum sander re-furbed that I bought on CL. That will be a nice addition.MMBGE / Large BGE / XL BGE (Craigslist Find) / SF30x80 cabinet trailer - "Ol' Mortimer" / Outdoor kitchen in progress.

RECOVERING BUBBLEHEAD

Southeastern CT. -

nolaegghead said:@CTMike Nice shop! I'm jelly of your Powermatics.I actually ordered a 2nd dust extractor last night. The Festool CT15 has been out of stock everywhere so I ordered the smaller Fein with a 5.9G tank. I need it for my Gretna shop where I keep all my wood - I try to rough cut it there and then bring to my house shop where I have the beast Festool CT26.I have a couple big shop dust collectors....one is the Grizzly and the other a cheaper HFNeed to plumb those up to the big tools.Metal working stuff is another rabbit hole. I have to admit that I'm pretty diversified on shop equipment.I'm trying to get a Grizzly drum sander re-furbed that I bought on CL. That will be a nice addition.saw dust and welding, what could possibly go wrongfor osha one year i had to train the welders about fire safety, i had the firedept send over sparky the fire dog and the first grader cartoons and we all got certified for osha. was disappointing that sparky didnt dress up for the part.fukahwee maineyou can lead a fish to water but you can not make him drink it

Categories

- All Categories

- 184K EggHead Forum

- 16.1K Forum List

- 461 EGGtoberfest

- 1.9K Forum Feedback

- 10.5K Off Topic

- 2.4K EGG Table Forum

- 1 Rules & Disclaimer

- 9.2K Cookbook

- 15 Valentines Day

- 118 Holiday Recipes

- 348 Appetizers

- 521 Baking

- 2.5K Beef

- 90 Desserts

- 167 Lamb

- 2.4K Pork

- 1.5K Poultry

- 33 Salads and Dressings

- 322 Sauces, Rubs, Marinades

- 548 Seafood

- 175 Sides

- 122 Soups, Stews, Chilis

- 41 Vegetarian

- 103 Vegetables

- 315 Health

- 293 Weight Loss Forum