Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

Clean Burn - Lid Stuck/w Rutland?

XL Egg Owner Since Dec 2013 - Louisiana

Comments

-

I think we may have just found our Friday Night Thread....

Rockwall, Tx LBGE, Minimax, 22" Blackstone, Pizza Party Bollore. Cast Iron Hoarder.

-

I was hoping the one about smash burgers would be the friday thread

i think it got buffaloed2 LBGE, Blackstone 36, Jumbo Joe

Egging in Southern Illinois (Marion)

-

Not sure it was the rutland, my vote goes to the permatex. I dont wrap the therm anymore. I did a few times because I thought it was pretty awesome, but I believe you can clean all the crud you need from the egg going about 700 dome temp for 2 hours. I think the lump runs out at that point anyway.

-

It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.Re-gasketing the USA one yard at a time

-

@RRP, maybe this guy is Wes Johnson.....

Rockwall, Tx LBGE, Minimax, 22" Blackstone, Pizza Party Bollore. Cast Iron Hoarder.

-

UltraCopper max 700°

https://www.permatex.com/products/gasketing/ultra-series-gasket-makers/permatex-ultra-copper-maximum-temperature-rtv-silicone-gasket-maker/

I hate it when I go to the kitchen for food and all I find are ingredients!

MichaelCentral Connecticut -

TEXASBGE2018 said:@RRP, maybe this guy is Wes Johnson.....

If it really was that scum ball then I would have told him to take a sledge hammer and whack the dome just as hard as he could swing it!

If it really was that scum ball then I would have told him to take a sledge hammer and whack the dome just as hard as he could swing it!  Re-gasketing the USA one yard at a time

Re-gasketing the USA one yard at a time -

My only guess would be the Permatex....just didn't know if this had ever happened to anyone before.

XL Egg Owner Since Dec 2013 - Louisiana

-

What would cause it do by harder than when I first purchased. Just time....elements....?RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.XL Egg Owner Since Dec 2013 - Louisiana

-

How was the 1200º determined? Its hard to estimate high temps without a measuring device. Once you take a thermometer out of range its really not very useful.Southeast Florida - LBGE

In cooking, often we implement steps for which we have no explanations other than ‘that’s what everybody else does’ or ‘that’s what I have been told.’ Dare to think for yourself. -

jtcBoynton said:How was the 1200º determined? Its hard to estimate high temps without a measuring device. Once you take a thermometer out of range its really not very useful.

Agree, it was a rough guess based on dome thermometer. I got caught up with supper and forgot to take it out for clean burn. It wrapped around to 300-400 so that was a rough guess.XL Egg Owner Since Dec 2013 - Louisiana

-

I just had another thought. Besides the Permatex the culprit may have also been the creosote that was the build up inside your dome. As it got hotter some of it may have melted and leeched on the gasket before the rest of it burnt off.corey24 said:

What would cause it do by harder than when I first purchased. Just time....elements....?RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.Re-gasketing the USA one yard at a time -

Good point, but I know I've hit 1,200º before using my 200-1,000º Tel-Trus.jtcBoynton said:How was the 1200º determined? Its hard to estimate high temps without a measuring device. Once you take a thermometer out of range its really not very useful.

Re-gasketing the USA one yard at a time -

Important to note that the scale on the Tel-Tru high temp is not linear.Southeast Florida - LBGE

In cooking, often we implement steps for which we have no explanations other than ‘that’s what everybody else does’ or ‘that’s what I have been told.’ Dare to think for yourself. -

A clean burn is a waste. Scrub the inside with a ball of foil or a brush. Smelting iron is better accomplished on other apparatus.Michiana, South of the border.

-

@RRP Tell him to hit the base. It cost more.RRP said:TEXASBGE2018 said:@RRP, maybe this guy is Wes Johnson..... If it really was that scum ball then I would have told him to take a sledge hammer and whack the dome just as hard as he could swing it!

If it really was that scum ball then I would have told him to take a sledge hammer and whack the dome just as hard as he could swing it!  XLBGE, LBGE, MBGE, SMALL, MINI, 2 Kubs, Fire Magic Gasser

XLBGE, LBGE, MBGE, SMALL, MINI, 2 Kubs, Fire Magic Gasser -

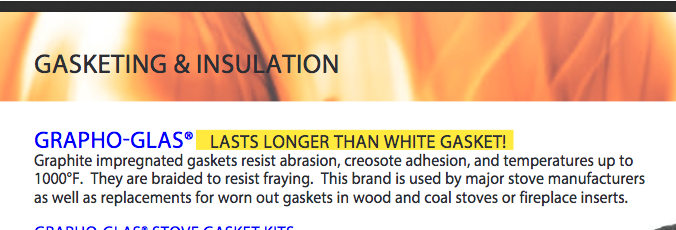

Can you document the 2200°? I’ve seen the highest of 1100°.RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.-----------------------------------------analyze adapt overcome2008 -Large BGE. 2013- Small BGE and 2015 - Mini. Henderson, Ky. -

Can I document the @2200º ?Mattman3969 said:

Can you document the 2200°? I’ve seen the highest of 1100°.

Well Rutland corporate technical folks told me that many years ago, but let me find it somewhere and I will post the link.Re-gasketing the USA one yard at a time -

What difference does it make? What are you cooking that needs 2200°??!!! My Rutland as been on my egg since 2009. I have baked pizzas at 900°. It's just as good as it was when I installed it. Ron's has been on his egg for several years longer than mine!

I hate it when I go to the kitchen for food and all I find are ingredients!

MichaelCentral Connecticut -

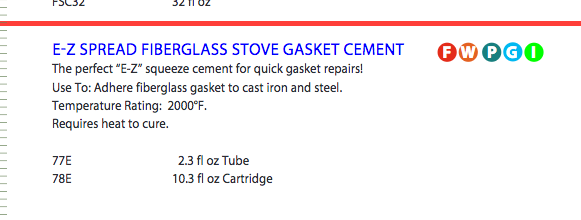

I just checked my tube of PermaTex and it states max continuous temp of 600 degrees and intermittent of 700. There's likely a bit of wiggle room there but likely not more than 100 degrees. This leads me to believe that it was the PermaTex 'melting', then oozing through the gasket and bonding to the top dome when the Egg cooled.RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.

I will be keeping my clean burns at 600 from now on. It's also easier on the firebox ceramics.

-

Just a quick look on the Rutland website says this:

“Reality is that which, when you stop believing in it, doesn't go away.” ― Philip K. Diçk

“Reality is that which, when you stop believing in it, doesn't go away.” ― Philip K. Diçk -

Thanks @HeavyG for not calling me liar! But I still contend I was told 2,200 degrees by Rutland years ago. Just the same I plan to call Rutland technical support tomorrow and I will hence forth change my pat answer of 2,200 degrees to whatever they say. I will even try to receive an email.

Meanwhile I just Googled "melting point of fiberglass" and the answer is 2,075 degrees so I wonder if the Rutland link you posted refers to the heat tolerance of any or all of their adhesives and not the gasket material itself.

I think it is important to remember that only the tiny amount of the gasket is inside the BGE subject to the direct heat. And besides that I question if a BGE is even capable of reaching 2,075 degrees.Re-gasketing the USA one yard at a time -

This is from a Rutland product catalog and the 1000°F pertains to the gasket material:

From the same catalog, the info for the gasket cement they recommend which is rated for 2000°F:

From the same catalog, the info for the gasket cement they recommend which is rated for 2000°F: Makes sense that the adhesive would be rated for a higher temp than the gasket.“Reality is that which, when you stop believing in it, doesn't go away.” ― Philip K. Diçk

Makes sense that the adhesive would be rated for a higher temp than the gasket.“Reality is that which, when you stop believing in it, doesn't go away.” ― Philip K. Diçk -

+1. What’s the point/need of all these clean burns?? I think I did it once too, but haven’t for years. Grub still turns out well, despite that.Teefus said:A clean burn is a waste. Scrub the inside with a ball of foil or a brush. Smelting iron is better accomplished on other apparatus.#1 LBGE December 2012 • #2 SBGE February 2013 • #3 Mini May 2013A happy BGE family in Houston, TX. -

People made gaskets out of this permatex material and never had issues. Don’t think it’s the permatex or the gasket but maybe a sloppy cook who’s gasket might be covered in sauce that caused the dome to adhere to the base.kaybee said:

I just checked my tube of PermaTex and it states max continuous temp of 600 degrees and intermittent of 700. There's likely a bit of wiggle room there but likely not more than 100 degrees. This leads me to believe that it was the PermaTex 'melting', then oozing through the gasket and bonding to the top dome when the Egg cooled.RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.

I will be keeping my clean burns at 600 from now on. It's also easier on the firebox ceramics.-----------------------------------------analyze adapt overcome2008 -Large BGE. 2013- Small BGE and 2015 - Mini. Henderson, Ky. -

I believed that from the beginning but was trying to give the guy the benefit of the doubt! It just seems odd that in the 16 years I have been providing this service with at least 10 or 11 of those years suggesting the use of Permatex to adhere the Rutland that I have never heard the problem reported by the OP.Mattman3969 said:

People made gaskets out of this permatex material and never had issues. Don’t think it’s the permatex or the gasket but maybe a sloppy cook who’s gasket might be covered in sauce that caused the dome to adhere to the base.kaybee said:

I just checked my tube of PermaTex and it states max continuous temp of 600 degrees and intermittent of 700. There's likely a bit of wiggle room there but likely not more than 100 degrees. This leads me to believe that it was the PermaTex 'melting', then oozing through the gasket and bonding to the top dome when the Egg cooled.RRP said:It is probable that some Permatex that oozed out on top of your Rutland during your application became pliable causing the sticking. And when you say the gasket seems hard and crusty then that confirms my suspicion as the Rutland withstands 2,200º so a simple 1,200º at gasket level didn't cause it to be hard and crusty.

I will be keeping my clean burns at 600 from now on. It's also easier on the firebox ceramics.Re-gasketing the USA one yard at a time -

“Never” have had a issue with mine with your suggested install. Thanks RRP!Plumbers local 130 chicago. Why do today what you can do tomorrow

weapons: XL, Minie, old gasser, weber, v10 Bradley smoker and sometimes talent!

Bristol, Wisconsin

Categories

- All Categories

- 184K EggHead Forum

- 16.1K Forum List

- 461 EGGtoberfest

- 1.9K Forum Feedback

- 10.5K Off Topic

- 2.4K EGG Table Forum

- 1 Rules & Disclaimer

- 9.2K Cookbook

- 15 Valentines Day

- 118 Holiday Recipes

- 348 Appetizers

- 521 Baking

- 2.5K Beef

- 90 Desserts

- 167 Lamb

- 2.4K Pork

- 1.5K Poultry

- 33 Salads and Dressings

- 322 Sauces, Rubs, Marinades

- 548 Seafood

- 175 Sides

- 122 Soups, Stews, Chilis

- 40 Vegetarian

- 103 Vegetables

- 315 Health

- 293 Weight Loss Forum