Welcome to the EGGhead Forum - a great place to visit and packed with tips and EGGspert advice! You can also join the conversation and get more information and amazing kamado recipes by following Big Green Egg to Experience our World of Flavor™ at:

Want to see how the EGG is made? Click to Watch

Facebook | Twitter | Instagram | Pinterest | Youtube | Vimeo

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

Slow and low on a MIni Help

Options

aaind

Posts: 235

Last night I got my minni ,wanted to do a 225-250 just for fun.

Went to 300 and had it almost shut down 1/6 " bottom vent .

So 6 am I found a way to get rid of the sloppy play in the vents with steel wool type of tape ,worked super I just lit the lump from last night and it worked well 250 for 2 hrs plus ,I thought it would be fun to see how long it would go so I stired it up and filled it (new on top and setting the same ) ,at 12 when I got home it was 400

Dont really get it ?? Need advice

Thanks Dave

Went to 300 and had it almost shut down 1/6 " bottom vent .

So 6 am I found a way to get rid of the sloppy play in the vents with steel wool type of tape ,worked super I just lit the lump from last night and it worked well 250 for 2 hrs plus ,I thought it would be fun to see how long it would go so I stired it up and filled it (new on top and setting the same ) ,at 12 when I got home it was 400

Dont really get it ?? Need advice

Thanks Dave

Comments

-

did you check the seal with a dollar bill?SEE YOU IN FLORIDA, March 14th and 15th 2014 http://www.sunshinestateeggfest.com You must master temp, smoke, and time to achive moisture, taste, and texture! Visit www.bubbatim.com for BRISKET HELP

-

i will start at the beginning, although some of this will be repeat ... listen to bubba tim

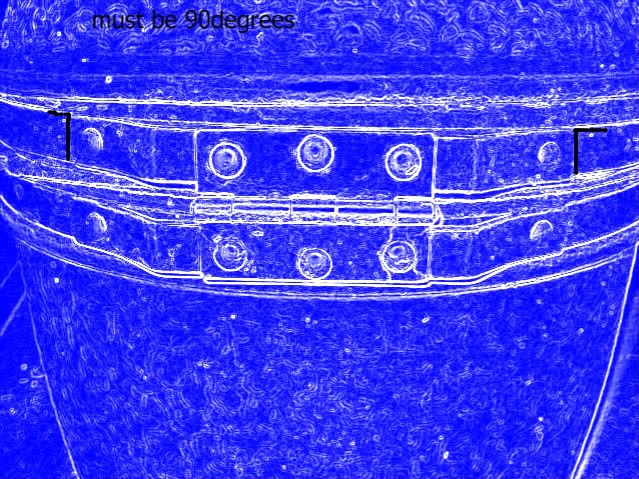

here goes: do the dollar bill test and check your hinge if it is riveted off square, as mine was , it will never seal . there was a problem with hinges and bge is aware of it

seal the draft door

grind the ribs so underside of dfmt sits flat on top of chimney

except the screw that holds the daisy wheel to the dmft is too long so it won't sit flat..sorry no pics but i saved the screw i think and will take one.. go to hardware store for new screw..

let us know if your are still having problems and make sure to wait about an hour so egg is fully heated before beginning test ..

bill -

Did the grinding and did $1 test was a little better on front but was not relly loose on the back , sealed the draft door with steel wool tape ,But it was 250 for almost 2 hrs then put more coal on ? could that make more heat or is that just more reserve ,or I just have a leak

Thanks Dave -

new screw [yes i know it is a bolt but screw sounds better]

old screw

-

i think adding the coal probably skewed your results load it with lump bring it to temp and walk away.. i got five hours out of mine when dioing 2.5 lbs of beef shorts with a soapstone place setter.

good luck let us know anbe sure to sheck your hinge and your screw.

bill -

I used the Dremel tool to take off the the screw and ground down the casting on the wheel it fits perfect now

Dave -

more reserve. Think about this, your fire (heat) is controled by the amount of oxegen let in to the fire chamber/box. If you can control the oxegen you can control your heat. Bottom line, you gota leak! Check your bands both upper and lower. Lossen and then tighten again. You may want to rethink low and slow on the mini, it can be done and a lot of eggers do it. We use ours for cooks above low and slow. 300 plus.SEE YOU IN FLORIDA, March 14th and 15th 2014 http://www.sunshinestateeggfest.com You must master temp, smoke, and time to achive moisture, taste, and texture! Visit www.bubbatim.com for BRISKET HELP

-

sounds like you have all the mechanical issues well taken care of... clean it i]out real well including lifting out the fire box load it up and see what happens good luck

bill -

The steel wool is a good thought, but remember steel wool is a great way to light a fire, very flamable.

The fire box in the mini is a relative long way away from the vent door so but some lump really sparks.

A thin strip of gasket material would also possibly work.

My 2¢

GG -

Hey Kent,

I stopped by HD and picked up some red fire brick. I think a new heavy duty mini platestter will be made this weekend with my diamond bladed skill saw..I will take some pics and post. :PSEE YOU IN FLORIDA, March 14th and 15th 2014 http://www.sunshinestateeggfest.com You must master temp, smoke, and time to achive moisture, taste, and texture! Visit www.bubbatim.com for BRISKET HELP -

bill wrote:new screw [yes i know it is a bolt but screw sounds better]

old screw

hellz yes on the victory. -

Good idea for a project.

GG -

prima pils and hop devil..

-

You really think that my steel wool will go up in flames (OHH BOY)

But if you put new lump on top of old lit lump with same air settings will you get hotter fire ??? -

I am sure I will also ,I know it not like a large they arte so stable ( Just set it and forget it for hrs and hrs)

but if mine is tight and I think it is you should be able to do a 225- 250 ,but you are heating a very small

area I think its so quick to over heat dont you ? -

There is a possibility of steel wool igniting, a spark will do that with steel wool. We used it in scouts to light fires with flint and rock. I don't think it is a huge problem as you don't have a large 'fluffy' piece of steel wool sitting there.

Putting new lump over old burning lump at first will cause a decrease in temp.

The burn patters is from the surface to the air source.

I purchased a 1qt sauce pan which I use to gather up cold lump as well as hot lump.

If I need to add new lump I take 1 scoop of burning lump out. Put in the new lump and then the pan of burning lump on top, works great.

I read your adding lump post and had wondered a couple of things.

Is it possible any of your vents changed?

Did you stir the old burning lump before adding the new?

I have been doing some testing with adding new to old lump and also with cold used lump on a new fire... It seems that not stirring or tamping down is a better method.

Let's say you stirred or tamped down you old burning lump and then added new lump. The stirring/tamping moved smaller pieces towards fire grate and air holes in the fire box.

Those air paths are now somewhat restricted. The new lump on top of the existing burning lump as blocked any top side air.

As the lump burns the fire moves to the air source. Once the lump in the fire great clears from the holes more air will flow into the lump and more air = higher temps.

Anyway just some thoughts.

GG

Categories

- All Categories

- 182.7K EggHead Forum

- 15.7K Forum List

- 459 EGGtoberfest

- 1.9K Forum Feedback

- 10.3K Off Topic

- 2.2K EGG Table Forum

- 1 Rules & Disclaimer

- 9K Cookbook

- 12 Valentines Day

- 91 Holiday Recipes

- 223 Appetizers

- 516 Baking

- 2.4K Beef

- 88 Desserts

- 163 Lamb

- 2.4K Pork

- 1.5K Poultry

- 30 Salads and Dressings

- 320 Sauces, Rubs, Marinades

- 543 Seafood

- 175 Sides

- 121 Soups, Stews, Chilis

- 35 Vegetarian

- 100 Vegetables

- 313 Health

- 293 Weight Loss Forum