Share your photos by tagging us and using the hashtag #BigGreenEgg.

Want to see how the EGG is made? Click to Watch

Tighten bands when egg is still hot?

Comments

-

I asked this question here a while ago and the overwhelming response was NO! Don`t do it.

-

Thanks @Ktim I'm glad I asked before I tried. Did you ever find a solution to the shifting bands on your egg or do you have to realign after every high temp cook?

-

My egg is nearly 5 years old. I haven't had to make any adjustments to anything and I have cooked from 250-900°. No band slippage at all. I finally checked band tightness about a month ago (first time ever). Still good.Sounds like you don't have the bands tight enough to begin with. How bent are your band bolts? They should look about like this...

And DO NOT do it while it's hot!

And DO NOT do it while it's hot!I hate it when I go to the kitchen for food and all I find are ingredients!

MichaelCentral Connecticut -

I did not have a problem but was just doing 1 month maintenance. It sounded like a good idea but popular opinion was no.

-

Maybe a better pic...

I hate it when I go to the kitchen for food and all I find are ingredients!

MichaelCentral Connecticut -

My bolts are bent but maybe not enough. Yours do appear to be bent more. Maybe I just need to crank down on the bolts more then I think I do.Carolina Q said:My egg is nearly 5 years old. I haven't had to make any adjustments to anything and I have cooked from 250-900°. No band slippage at all. I finally checked band tightness about a month ago (first time ever). Still good.Sounds like you don't have the bands tight enough to begin with. How bent are your band bolts? They should look about like this... And DO NOT do it while it's hot!

And DO NOT do it while it's hot!

-

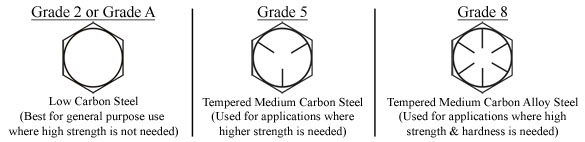

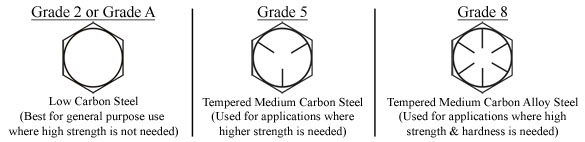

Neither of those pics are of my egg, but that's about how much mine are bent.BTW, should you ever have to replace them, you will need Grade 5 carriage bolts. Identified by the three markings on the head. A real hardware store will have them (Ace, Do-it-Best, True Value). Not sure about HD or Lowe's. Your dealer will, of course, but he'll probably charge more.

I hate it when I go to the kitchen for food and all I find are ingredients!

MichaelCentral Connecticut -

To each his own.

I tightened mine down while the egg was cooling one day. Close to 200*F and I gave the bolts a few more turns and get them to bend a bit. I had a problem with the dome and the base not matching up, huge under bite, gasket getting damaged on the rear side of the grill near the hinge. Lined it up, cranked it down, cooked, and tightened it down at the end and I haven't had to touch it since, and the new gasket discoloring shows that I have it pretty darn close to even, and the gasket isn't messing up.

It was the only thing that worked for me.

-FATC1TY

Grillin' and Brewing in Atlanta

LBGE

MiniMax -

I had problems with my dome falling out of alignment every time I got my temp up to 700 plus. So, after aligning and then warming the Egg, I torqued the bolts to 10# and all is good. No more alignment issues at high temps.Joe - I'm a reformed gasser-holic aka 4Runner Columbia, SC Wonderful BGE Resource Site: http://www.nakedwhiz.com/ceramicfaq.htm and http://www.nibblemethis.com/ and http://playingwithfireandsmoke.blogspot.com/2006/02/recipes.html

What am I drinking now? Woodford....neat -

Thanks for the help Carolina Q. My bolts still seems to be ok so I realigned and cranked them down tight and we will see what happens. Doing a 550 degree cook tonight which should be a pretty good test.Carolina Q said:Neither of those pics are of my egg, but that's about how much mine are bent.BTW, should you ever have to replace them, you will need Grade 5 carriage bolts. Identified by the three markings on the head. A real hardware store will have them (Ace, Do-it-Best, True Value). Not sure about HD or Lowe's. Your dealer will, of course, but he'll probably charge more.

@FATC1TY and @4Runner I'm glad to hear this worked for you. If cranking the bolts down tighter then I think I need to doesn't work, I will probably resort to what you did and tighten them down with the egg warm.

-

I used stainless steel carriage bolts on my bands today when replacing the dome. I couldn't find Grade 5 or 8 carriage bolts only hex heads. I have no idea how strong the stainless steel bolts are compared to Grade 5 or 8. Hopefully it'll be okay.

Rocky Top, TN — Large BGE • Cast Iron Grate & Platesetter • Rockwood Lump

-

I just a tightened them cold with the torque wrench to the 120 in-lbs per instructions. I don't want to void a warranty, but I've read you would break the bolts before the ceramic.

http://www.grill-repair.com/blog/2013/big-green-egg-spring-assisted-band-replacement-instructions/Pittsburgh, PA - 1 LBGE -

Double nutting helps to!!Hows ya gettin' on, me ol ****?Kippens.Newfoundland and Labrador. (Canada).

-

Pittsburgh, PA - 1 LBGE

-

#-o not gonna touch this one.

@MagicMike +1 always adjust while cool. Never while hot.LBGE 2013 & MM 2014Die Hard HUSKER & BRONCO FANFlying Low & Slow in "Da Burg" FL -

I'm glad all the resident mechanical engineers jumped on this.

Let me say that designing around specifications for a product is pretty much how it's done. If you need an oven to cover 170F to 550F (typical for a kitchen), you engineer your oven to handle those extremes.

If that dome is loose at 700F, you can tighten it just enough to stay on, and when it cools down, you know you met the specification it was designed around - the expansion differential was to keep the dome tight at some torque spec from ambient to 700 or whatever the upper limit specs are.

I'm saying, if the dome is loose on a pizza cook, tighten it until it's secure. Don't try to torque the Eff out of it, but just make you barely tighten it to work, hold the lid on, and the specifications of the design will keep it from busting apart when it cools. You need to understand that to do this, if you don't, don't try.

I'm not encouraging anyone to do this, but this a logical conclusion of specifications we all know (the cooking range) and given a bit of over-design is engineered in anything that goes to consumers that gets abused,... and basic logic.

______________________________________________I love lamp.. -

OK, I know I'm going to get a bunch of "better safe than sorry" folks that say - but I'm gonna read the manual made for average consumers, or maybe I'll void the warranty doing this. For those of you, ignore this post. This is bad advise. If you are a mechanical engineer, discussion is open.

______________________________________________I love lamp.. -

I tend to agree with this @nolaegghead. And definitely don't try if you don't understand it. If you muscle eff it while hot ain't nothing good gonna come from it except for a warranty dome.LBGE 2013 & MM 2014Die Hard HUSKER & BRONCO FANFlying Low & Slow in "Da Burg" FL

-

Stainless is between grade 2 and 3. It can't be heat treated or tempered the same way as steel. Might be fine though.EggHead_Bubba said:I used stainless steel carriage bolts on my bands today when replacing the dome. I couldn't find Grade 5 or 8 carriage bolts only hex heads. I have no idea how strong the stainless steel bolts are compared to Grade 5 or 8. Hopefully it'll be okay.

______________________________________________I love lamp.. -

Funny. I just looked on the BGE website and they had downloadable PDF assembly instructions. I guess they think their buyers are illiterate. It's all pictures. Since it's all pictures, I'm gonna assume they want you to assemble/adjust it while it's cold. You wouldn't put the firebox in the base and start a fire to assemble it would you??? Why would you heat it up to torque it down?Steven

Mini Max with Woo stone combo, LBGE, iGrill 2, Plate Setter,

two cotton pot holders to handle PS

Banner, Wyoming -

Thanks for the info... I'll keep an eye on it after the first few cooks. Realistically, what is the problem in using a regular carriage bolt vs a grade 5 or 8 bolt? I know the higher grades are harder, but if we're only torquing these bolts to keep the dome tight while lifting, I guess I don't understand the reason.nolaegghead said:

Stainless is between grade 2 and 3. It can't be heat treated or tempered the same way as steel. Might be fine though.EggHead_Bubba said:I used stainless steel carriage bolts on my bands today when replacing the dome. I couldn't find Grade 5 or 8 carriage bolts only hex heads. I have no idea how strong the stainless steel bolts are compared to Grade 5 or 8. Hopefully it'll be okay.Rocky Top, TN — Large BGE • Cast Iron Grate & Platesetter • Rockwood Lump

-

I'm not suggesting that. I'm just saying if the dome is literally falling out while you're cooking you can torque it down enough so it doesn't fall apart.stemc33 said:Funny. I just looked on the BGE website and they had downloadable PDF assembly instructions. I guess they think their buyers are illiterate. It's all pictures. Since it's all pictures, I'm gonna assume they want you to assemble/adjust it while it's cold. You wouldn't put the firebox in the base and start a fire to assemble it would you??? Why would you heat it up to torque it down?

______________________________________________I love lamp.. -

i tighten mine up around 325 dome

the dome is still tight at 900 dome, but not at 1200 dome

the dome is still tight at 900 dome, but not at 1200 dome ) fukahwee maineyou can lead a fish to water but you can not make him drink it

) fukahwee maineyou can lead a fish to water but you can not make him drink it -

I gotcha @nolaegghead. I was just being facetious. When I worked in the shipyards about 25 years ago, we would use torches to expand big corroded nuts and use slugging wrenches to get them loose. Sometimes it would take an hour of heating and beating for one nut. Anyway, what you said made since. I imagine the bands on the egg expand more than the ceramic, at least at different rates possibly making the dome loose. I would rather tighten a hot loose dome than pick up a broken dome.Steven

Mini Max with Woo stone combo, LBGE, iGrill 2, Plate Setter,

two cotton pot holders to handle PS

Banner, Wyoming -

Maybe we are over thinking all this a bit? I mean, if you notice the dome falls out of alignment every time you cook, just tighten it a bit while hot. If that works, all good. If you don't have this issue...move on. I don't see a warranty issue at all with this unless you go all Hulk Hogan or something.Joe - I'm a reformed gasser-holic aka 4Runner Columbia, SC Wonderful BGE Resource Site: http://www.nakedwhiz.com/ceramicfaq.htm and http://www.nibblemethis.com/ and http://playingwithfireandsmoke.blogspot.com/2006/02/recipes.html

What am I drinking now? Woodford....neat -

I'm with @4Runner here.. I'm smart enough to know what I can and can't do with it. I didn't have to go all wild with it, but a quick snug of the bolts as a final turn while it was warm was enough to make sure my bands stopped slipping and moving around causing alignment issues.

As with most things, YMMV.

-FATC1TY

Grillin' and Brewing in Atlanta

LBGE

MiniMax -

What's the problem with following the instructions? ONE HUNDRED TWENTY INCH POUNDS. Normally torques are for dry nuts and bolts cold. This is not very tight, but is enough to hold the bands according to those who should know-the manufacturer.

Bob

who did read the instruction manual.

Cookin' on the coast

Shellman Bluff, GA

Medium BGE -

Great post @Coastalcooker that is exactly what I did and no problems, snugged up the bolts 1 month later and have had no problems since.

-

Been there and done that. Bought a new hinge assembly and torque wrench and thus my issue until I set them at 10# when warm.Joe - I'm a reformed gasser-holic aka 4Runner Columbia, SC Wonderful BGE Resource Site: http://www.nakedwhiz.com/ceramicfaq.htm and http://www.nibblemethis.com/ and http://playingwithfireandsmoke.blogspot.com/2006/02/recipes.html

What am I drinking now? Woodford....neat -

Thanks everyone for the help and advice.

2 days ago I realigned and tightened the bands on my egg while it was cold. I let it sit for about 15 mins before I came back to it. Before lighting a fire I decided to check the band bolts again and to my surprise they were not as tight as they were 15 mins ago. I decided to tighten them up again, waited 15 more mins then tightened again. I did this 3 times before the bolts no longer became loose on the egg sitting there cold. I then proceeded to light the lump and get it to 550 degrees to cook some burgers. The lid and bands did not move this time during the cook! Time will tell if this is a true solution or not but at least it's progress.

Categories

- All Categories

- 182.7K EggHead Forum

- 15.7K Forum List

- 459 EGGtoberfest

- 1.9K Forum Feedback

- 10.3K Off Topic

- 2.2K EGG Table Forum

- 1 Rules & Disclaimer

- 9K Cookbook

- 12 Valentines Day

- 91 Holiday Recipes

- 223 Appetizers

- 516 Baking

- 2.4K Beef

- 88 Desserts

- 163 Lamb

- 2.4K Pork

- 1.5K Poultry

- 30 Salads and Dressings

- 320 Sauces, Rubs, Marinades

- 543 Seafood

- 175 Sides

- 121 Soups, Stews, Chilis

- 35 Vegetarian

- 100 Vegetables

- 313 Health

- 293 Weight Loss Forum